Home > News

> News Information

Home > News

> News Information

In home kitchens or professional dining environments, the cutting and slicing disc is an important component of kitchen appliances such as food processors and multifunctional food processors. Its performance and maintenance directly affect the efficiency and quality of food processing. Proper maintenance not only ensures the sharpness and precision of the cutterhead, but also effectively extends its service life and reduces replacement costs. The following is a detailed guide on the maintenance and upkeep of the slicing cutter head, aimed at helping users better understand and practice this process.

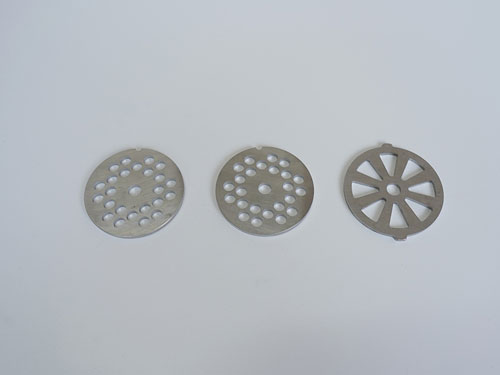

1、 Understand the structure and material of the cutterhead

Firstly, it is crucial to be familiar with the basic structure of the cutting and slicing disc. Most disc cutters are composed of blades, fixed frames, adjustment knobs, and other components, and are often made of stainless steel or high carbon steel to ensure the hardness and durability of the blades. Stainless steel has become the preferred material for many high-end cutterheads due to its strong corrosion resistance and easy cleaning. Understanding the specific structure of the cutterhead helps to be more meticulous during maintenance and avoid damage caused by misoperation.

2、 Daily usage precautions

1. Food preparation: Before using the knife disc, ensure that the food has been cleaned thoroughly and hard parts such as bones and nuclei have been removed to prevent damage to the blades. For larger ingredients, they should be cut into small pieces in advance for easy knife handling.

2. Moderate adjustment: Adjust the spacing of the blades by adjusting the knob according to the thickness of the required ingredients. Be careful and cautious when adjusting to avoid excessive force that may cause the knob to loosen or be damaged.

3. Uniform feeding: During operation, the ingredients should be fed into the cutting disc at a constant speed to avoid overloading the disc, affecting cutting efficiency, and even damaging the machine.

4. Safe operation: Before use, check if the cutterhead is securely installed. Wear protective gloves during operation to avoid direct contact with the blade. After use, disassemble and clean the machine only after it has completely stopped.

3、 Regular cleaning and maintenance

1. Instant cleaning: After each use, immediately disconnect the power and wait for the disc to cool completely before using a soft brush or toothbrush to remove any remaining food debris. Avoid using metal brushes or hard tools to avoid scratching the blades.

2. Deep cleaning: At regular intervals (recommended once a week), remove the cutter head, soak it in warm water, add a small amount of neutral detergent, and gently wipe the blades and various components with a soft cloth. Be careful not to completely immerse the cutterhead in water to prevent the motor from getting damp.

3. Rust prevention treatment: After cleaning, wipe off the moisture with a clean soft cloth, especially the blade part, and apply a thin layer of edible oil to prevent rusting. When storing, the knife disc should be placed in a dry and ventilated place to avoid humid environments.

4. Lubrication and maintenance: For cutterheads with moving parts, such as adjustment knobs, some food grade lubricating oil can be applied appropriately to maintain smooth rotation and reduce wear.

4、 Common Problems and Solutions

1. Blunt blade: After long-term use, the blade may become dull due to wear and tear. At this point, a specialized knife sharpener or fine sandpaper can be used to gently polish the edge of the blade to restore its sharpness. Note that the grinding direction should be consistent with the original cutting direction of the blade to avoid damaging the blade structure.

2. Increased noise: If the machine noise significantly increases during use, it may be due to loose cutterhead or worn bearings. Stop the machine immediately for inspection, tighten the screws of the cutterhead, and replace worn bearings if necessary.

3. Uneven cutting: Poor cutting effect may be due to improper adjustment of blade spacing or severe blade wear. Adjust the blade spacing again and check if the blades need to be replaced or polished.

5、 Professional maintenance and upgrade suggestions

For high-end commercial equipment, it is recommended to regularly invite professional technicians for comprehensive inspection and maintenance, including motor performance testing, blade wear assessment, and necessary replacement. In addition, with the development of technology, new types of cutting discs are constantly being introduced in the market, such as blades made of ceramic material, which have higher hardness and wear resistance, and can be upgraded in a timely manner to improve cutting efficiency and food processing quality.

6、 Conclusion

As a reliable assistant in the kitchen, the maintenance and upkeep of the cutting and slicing disc cannot be ignored. By following the above guidelines, not only can you ensure that the cutterhead is always in the best working condition, but you can also effectively extend its service life, bringing more convenience and fun to your cooking life. Remember, every meticulous maintenance is a respect for food and a pursuit of a quality life. In the future, let's enjoy the fun of cooking together and explore more possibilities of delicious food.

.jpg)