Home > News

> News Information

Home > News

> News Information

The juicer, a common small household appliance in modern kitchens, has become the preferred tool for many families to make healthy drinks due to its convenient operation and efficient juicing ability. In the core components of a juicer, the blade undoubtedly plays a crucial role. It not only determines the efficiency of juice extraction, but also directly affects the taste and nutritional value of the juice. This article will delve into the design principles of juicer blades and reveal how they achieve the art of precise cutting.

The working principle of juicer blades mainly relies on high-speed rotation and material contact. The blade rotates at high speed through the shaft connected to the motor, which provides power. When materials such as fruits and vegetables are put into the juicing container of the juicer, the blades rotate at high speed to cut and crush the materials. In this process, the juice in the material is cut open and thrown out with the rotating blade, and finally discharged through the aperture of the juicer, achieving separation from the overall material to the juice.

In order to achieve precise cutting, the design of juicer blades needs to consider multiple aspects. Firstly, the sharpness of the blade. The sharpness of the blade directly affects the cutting ability, which in turn affects the juice extraction efficiency. Sharp blades can quickly decompose fruits and vegetables, improving juice extraction speed. Therefore, in the design process, the blade needs to use high-quality materials such as high-strength steel or tungsten carbide, and ensure the uniformity and sharpness of the blade through precise processing technology. These materials not only have high hardness, good strength, and strong wear resistance, but also greatly improve cutting ability and service life.

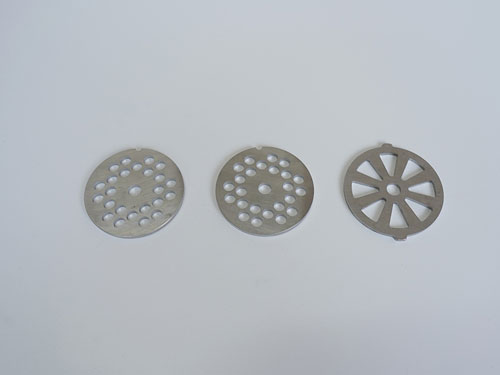

Next is the structural design of the blade. The juicer blade usually adopts a multi blade design, which means that there are multiple cutting edges distributed on the blade. This design can increase the cutting area and improve cutting efficiency. At the same time, the structure of the blade also needs to consider the characteristics of the material. For fruits and vegetables with high fiber content, the blade needs to have stronger cutting ability to cope with fiber pulling and entanglement. Therefore, in design, the cutting performance of the blade can be enhanced by increasing its thickness, adjusting the angle and shape of the cutting edge, and other methods.

In addition to sharpness and structural design, the juicer blade also needs to consider the way it is combined with the body. The joint between the blade and the machine body should be tight and firm, able to withstand the force of high-speed rotation of the juicer. When using a juicer, the moisture content and fiber quality of fruits and vegetables are different, which will have different effects on the combination of the blade and the body. Therefore, in the design process, it is necessary to use appropriate connection methods, such as threaded connections, snap connections, etc., to ensure that the blade will not loosen or fall off during high-speed rotation. At the same time, it is also necessary to consider the ease of disassembly and cleaning of the blades, so that users can easily perform maintenance and upkeep during use.

In the process of achieving precise cutting, the juicer blade also needs to consider the cutting path of the material. The cutting path refers to the trajectory of the material being cut and crushed by the blade. Optimizing the cutting path can make the material more fully in contact with the blade, improving cutting efficiency and juice extraction effect. Some advanced juicer designs adopt unique cutting paths, such as spiral cutting, multi-directional cutting, etc., which can better adapt to fruits and vegetables of different shapes and sizes, ensuring that every part can be evenly cut.

Spiral cutting path, formed by the spiral motion of the blade, gradually pushes and cuts the material during the juice extraction process, which can more effectively squeeze out the juice and reduce waste. The multi-directional cutting path, on the other hand, uses blades to cut in different directions, ensuring that the material is subjected to all-round cutting force in the juice container, ensuring finer cutting and improving the taste and nutritional value of the juice.

In addition, the design of juicer blades also needs to consider noise control. The high-speed rotating blade will generate certain noise. In order to improve the user experience, designers will optimize the blade structure, material selection, and motor control, striving to reduce noise while ensuring cutting effect.

In summary, the design of juicer blades is a comprehensive project that involves multiple aspects such as sharpness, structural design, bonding methods, cutting paths, and noise control. Only by considering these factors comprehensively can we create an efficient, durable, and convenient juicer that brings health and deliciousness to families.

.jpg)