Home > News

> News Information

Home > News

> News Information

In the hardware and small household appliance industry, the blade is a key component, and its processing technology directly affects the performance, durability, and user experience of the product. This article will delve into the entire process of material selection, design, manufacturing, and final product of metal small household appliance blades, aiming to reveal the mysteries of this precision manufacturing field.

1、 Material selection: Dual consideration of performance and cost

The selection of materials for metal and small household appliance blades is the first step and a crucial part of the processing technology. Common blade materials include stainless steel, high-speed steel, hard alloys (such as a mixture of tungsten carbide and cobalt), etc. Each material has its unique physical and chemical properties and is suitable for different application scenarios.

Stainless steel: Due to its excellent corrosion resistance and toughness, it is often used in the manufacturing of blades for small household appliances such as razors and food processing machines. Although stainless steel blades have relatively low hardness, they excel in being affordable, easy to process, and able to meet general usage needs.

High speed steel: With its high hardness, high wear resistance, and good thermal stability, it performs well in cutting high hardness materials, such as woodworking saws, carving machine blades, etc. However, the manufacturing cost of high-speed steel is high and the processing difficulty is relatively high.

Hard alloy: It is an ideal choice for high-end hardware and small household appliance blades. It is made by mixing, pressing, and sintering metal powders such as tungsten carbide and cobalt, and has extremely high hardness, strength, and wear resistance. It is suitable for situations that require long-term high load operation, such as drill bits and saw blades in electric tools. The machining process of hard alloy blades is complex, but the finished product has excellent performance and is a signature component of high-quality small household appliances.

2、 Design and Mold Manufacturing

After selecting the materials, the next step is the design phase of the blade. Designers need to determine key parameters such as the shape, size, and blade angle of the blade based on the product's usage requirements, power level, speed, and other parameters. At this stage, it is necessary to comprehensively apply multidisciplinary knowledge such as material mechanics, thermodynamics, and tribology to ensure that the blade can cut efficiently while maintaining sufficient durability and safety in practical use.

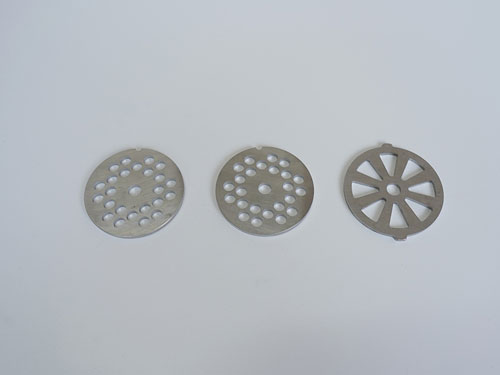

After the design is completed, corresponding stamping molds or precision machining equipment need to be made. For small and thin blades, steel strips or plates can be directly stamped and formed; For blades with complex shapes or high-precision requirements, high-precision equipment such as CNC machining centers and laser cutting machines need to be used for processing.

3、 Manufacturing and Processing

Manufacturing and processing are the core processes of forming metal and small household appliance blades. Taking hard alloy blades as an example, their manufacturing process can be roughly divided into the following steps:

1. Mixing and Pressing: After mixing tungsten carbide powder and cobalt powder in a certain proportion, a highly dense billet is made through pressing technology. This step requires strict control of the mixing ratio and pressing pressure of the powder to ensure the uniformity and density of the billet, laying a solid foundation for the subsequent sintering process.

2. Sintering: Place the pressed billet in a high-temperature furnace for sintering treatment. At high temperatures, tungsten carbide reacts chemically with cobalt to form a hard hard alloy structure. The precise control of sintering temperature, time, and furnace atmosphere has a decisive impact on the performance of finished blades.

3. Precision machining: The sintered blade needs to undergo multiple precision machining processes, including grinding, polishing, etc., to achieve the required dimensional accuracy and surface smoothness. This process requires highly skilled technicians to operate advanced processing equipment to ensure that each blade meets strict quality standards.

4. Edge treatment: As a critical part of the blade, edge treatment is particularly important. By using special grinding techniques, sharp edges are formed while maintaining the stability and durability of the edges. The shape and angle of the cutting edge directly affect the cutting efficiency and the service life of the blade.

4、 Quality Control and Testing

Strict quality control is required at every stage of the manufacturing process. From the inspection of raw materials, to sampling and testing during the manufacturing process, to comprehensive testing of finished products, every process is crucial. Through various methods such as hardness testing, wear resistance testing, and cutting efficiency testing, we ensure that each blade meets the design requirements and can perform at its best in practical use.

5、 Application and Feedback

Hardware small household appliance blades are ultimately used in various small household appliances, and their performance directly affects user experience and product reputation. Therefore, collecting user feedback and evaluating the performance of blades in actual use is of great significance for continuously improving design and optimizing processes. Meanwhile, with the continuous advancement of technology, the emergence of new materials and processes has provided unlimited possibilities for the innovation and development of hardware and small household appliance blades.

.jpg)